Qatalum’s Pitch Fume Treatment in the Paste Plant, optimises capture and destruction efficiency while cutting natural gas consumption – and the associated

carbon footprint – dramatically.

As we at Qatalum well know, in a carbon plant, treating emissions of polycyclic aromatic hydrocarbons (PAH) – some of which are known or suspected to be highly carcinogenic – is a vital priority. Since the introduction of paste mixer-coolers in the process fabrication of anodes, there has been a substantial proliferation of volatile compounds. Accordingly, emissions standards have become more stringent. It is therefore crucial that treatment technology can cope with more concentrated streams at the inlet, and lower emission requirements at the outlet.

How does this work in practice? The Eolios System, developed by Solios, delivers an unprecedented level of performance. Independent tests conducted in January 2013 at the Qatalum Green Anode Plant, the largest single line green anode plant in the world, found emissions of 1mg/Nm3 of PAH 16 (according to the NS 9815 Norwegian Standard) – a level never before achieved.

Eolios was introduced at Qatalum in 2010. Prior to this, it was first used at the Alcoa Moesjen Anode Plant in Norway in 2007 – where a PAH destruction efficiency improvement from 97 per cent to 99 per cent was observed. The system is an optimized combination of a dry scrubber, based on the adsorption of PAH on coke fines, and a Regenerative Thermal Oxidizer (RTO), using oxidation technology. This combination minimizes energy consumption while maximizing the treatment efficiency.

PAHs are the main components of coal tar pitch volatiles (CTPV). This is produced when coal tar pitch – a binder for the fabrication of anodes, which is solid at ambient temperature – is heated at around 160-200 degrees centigrade to turn it into liquid. PAHs can exists as light and heavy fractions, the former defined as having fewer than 3 aromatic rings in a molecule. Adding water to cool the anode paste substantially increases production of the light fraction, which are released in gaseous form. To illustrate, in the Deschambault paste plant, tests showed that PAH emissions grew six-fold after the introduction of a paste-cooler.

The conventional treatment method is the dry scrubber process. It entails injecting coke fines in a gas stream loaded by pitch fumes, resulting in absorption of the pollutants. Pitch loaded fines are collected by a dust collector and reintroduced into the anode paste recipe, while the clean gases are released into the atmosphere. The recycling of the pitch loaded fines means there is neither waste stream nor product loss. The global capture efficiency of this method for heavy PAHs can be up to 99 per cent.

Of course, the drawback of the dry scrubbing system is that it is based on the ability of PAH to condensate. That works well for the heavy fractions, which condensate easily: the global capture efficiency of this method for such fractions can be 99 per cent. But the lighter PAHs – emissions of which, as we have seen, increase drastically when water is added to cool the anode paste – do not condensate so easily. If there is no condensation, no adsorption occurs and the pollutants pass through the bag filter without being captured.

Thus in order to improve the treatment efficiency of light PAHs, we need to harness different technologies using oxidation reactions. PAHs are comprised mainly of C-H (carbon-hydrogen) bonds which are easily broken by oxidation. This process converts them to carbon dioxide and water vapour.

How does this happen? An RTO is the industrial process which does this. The equipment comprises three main components:

- The combustion chamber, where the oxidation reaction occurs. The temperature in the combustion chamber is around 850-900°C.

Ceramics beds, which are used as heat exchangers. The aim is to store heat and to recover it to preheat the inlet gas flow, thus saving energy.

- The valve box, which consists of two valves for inlet and outlet ducts and a valve for purge for each chamber.

Put briefly, the raw gas is introduced via the valve box and pre-heated as they pass through the ceramics to achieve the desired temperature for the combustion of PAH. One or two seconds in the combustion chamber is enough time for the destruction of PAH. The clean gas is released though a second heat exchanger, while a third removes the remaining gas residues.

Eolios is a combination of the dry scrubber and the RTO. At Qatalum paste plant, the RTO unit specifically treats the high concentrated fumes collected from the paste cooler – which contain mainly water vapour and light PAH fractions. The fumes are heated with hot air into a mixing pot situated on the paste cooler, to avoid tar condensing in the duct. Following this process, diluted fumes enter into the RTO unit at a temperature of 150°C. Following treatment by the RTO, the clean gas is rejected to the atmosphere.

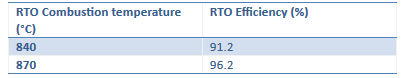

To measure the performance of this method, a set of flame ionisation detector measurements were taken to estimate the relationship between RTO temperature and destruction efficiency. The gas sample was continuously sampled into the FID, which measures the concentration of total volatile organic compounds. As the table illustrates, the results were impressive:

With environment emissions becoming ever more stringent, the importance of harnessing the full potential of innovative techniques and technologies cannot be overstated. Qatalum’s system sets a new benchmark in the Gulf, combining the advantages of two established techniques, the dry scrubber and the RTO, while minimising their weakness, all the while at a substantially lower operating cost.