The background event that set the plan to move into PT (precision tubing) was firmly endorsed after winning the Qatalum and Hydro Primary Quality award in 2014. This confirmed the success of 5 years of dedicated quality improvement work. In 2015 the Casthouse challenged itself to sustain quality leadership. To meet this challenge, the Casthouse decided upon two quality targets going forward turning quality into cash by sustaining quality leadership in the market and qualify for the supply of high margin products such as precision tubing (PT) to the market.

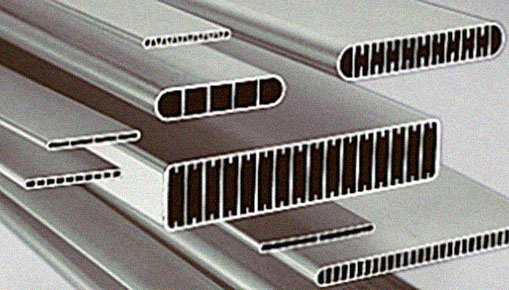

PT, (precision tubing) is used for a myriad of products from heat exchangers, audio products, PC products and consumer electronics.

The decision to move forward is not without its challenges both within Qatalum and that of entering a new market segment. None the less, the effort is worth the premium for PT which runs approximately US$ 200 above standard ingot.

Within the Casthouse, the cost reductions in place in 2015 saw a change of contractors within the Casthouse, with the introduction of 38 new directly supervised contractors unaware of Qatalum’s quality culture. This in parallel to the reduction of Casthouse manning according to the business plan. All of this needs to be aligned to sustain casthouse product quality, and maintain existing customer confidence and gain a PT customer base in a slow market.

Within the precision tubing market, Qatalum is a new supplier and with the current Casthouse running at full capacity, there is no time for product experimentation; given that the existing equipment needs to be tuned for the production of even higher quality melt with a very low tolerance for impurities.

The nature of the finished products require very high levels of purity to maintain product integrity. Any foreign material present in the extrusion billet coming out of Qatalum casthouse can potentially result in an extrusion failure, a hole in the extruded tube, and thus the final heat exchanger will leak.

However, preliminary actions taken within the Casthouse using its consistently reliable method of quality observations, reporting and problem solving initiated the qualification process and considered the following qualitative improvements: optimisation of casting parameters for reduced scrap and optimal microstructure, optimisation of the homogenizing process and optimization of product handling for best surface quality.