Qatalum is staying ahead of global industrial obligations on energy efficiency by investing in and implementing cutting edge technology. An example of how this energy efficient focus is being put into action comes from the installation of high-power converters (rectiformers) at the smelter in Mesaieed, Qatar.

Rectiformer – what is it?

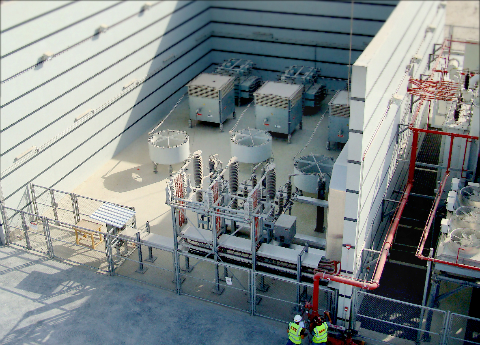

Associated with each smelter are five record-breaking rectiformers, some of the biggest and most powerful ever built in relation to their size to voltage output weighing in at more than 400 tons. Rectiformers, critically, control and convert the alternating current delivered by the power grid or onsite power plant into the required direct current (DC) that powers the electrolytic process that produces molten aluminium in the pots. If the power conversion station fails, the lines will shut down and the molten aluminium in the pots will solidify and incur costs that could run into millions of dollars.

Efficiency and innovation

Technological progress over the years has increased voltage limits from 1200 Volts DC to 2000 V DC. At Qatalum, the operational voltage will be 1500 V DC with a limit of 1650 V DC, but is designed for short periods to operate at up to 1750 V DC. According to the manufacturer ABB, this voltage increase enables the rectiformers to convert and deliver substantially more power than was previously possible. ABB added that fewer rectiformers are required than in the past resulting in cost savings and an increase in energy efficiency equivalent to approximately 18 percent.

For Qatalum, the real world context of such productivity is increased competitiveness, achieving operational excellence and sustaining environmental integrity.

Is Qatalum prepared for such technology?

Training to operate and maintain the Rectifier Stations has already been held on-site as well as in Switzerland. In keeping with Qatalum's training mandate and Operation Preparedness Planning (OPP), training before the start up of the potlines is an excellent advantage providing knowledge during commissioning and take over and to be expertly prepared for expected operation and maintenance.

Sources: ABB and www.controleng.com